At the Edge of Innovation:

Advanced Delivery Systems for Ambitious OEM Projects in the USA

R&D + Manufacturing in the USA for oral care, sublingual films, multi-chamber systems, suppositories, and dietary supplements

Who We Are

We are a US-based OEM/ODM that specializes in difficult, multi-component formulations — from professional in-office teeth-whitening systems engineered for summer heat-stability, to sublingual / orodispersible films (ODF) with high active loads, multi-chamber peroxide / activator dispensers, science–driven suppository delivery systems, and dietary supplement innovations. We combine rapid prototyping, analytical rigor, and design-for-scale manufacturing to move ideas from lab to launch on US timelines.

Why Customers Choose Us for the

“Too Hard” Projects

- Polymer-science DNA: We formulate with cellulose ethers, crosslinkable acrylates, block copolymers, PEG/lipid matrices, and smart rheology modifiers to tune adhesion, occlusion, and release.

- Event-temperature stability engineering: We design for 50 °C summer shipping, validated by accelerated stability.

- Multi-component architecture: Experience with binary systems (e.g., peroxide + activator) in dual-barrels, and two-stage strips.

- Regulatory-ready files: Cosmetic dossiers, ISO 22716 cosmetics GMP alignment, device-adjacent documentation where appropriate; US-based.

- Launch credibility: We have taken prestige beauty, dental, and Amazon-first brands from formulation to commercial scale – successfully launched on Sephora, Ulta, CVS, Amazon, and featured on Good Morning America multiple times; references and technical dossiers available under NDA.

Our Specialties

Oral-Care Systems: Whitening, Remineralization

- Professional & at-home whitening:

- Summer heat-stable peroxide systems (hydrogen peroxide) using oxygen-occlusion yet peroxide-compatible polymers, radical scavenger tuning, and water-activity control to maintain potency after 2 years.

Atrium’s room temperature stable professional teeth whitening gel delivering activated teeth whitening power in as little as 8 minutes. - Sensitivity-relieving activator (e.g., buffered catalysts) designed to co-mix in dual-chamber delivery systems with matched viscosities (±10%) for dose accuracy.

- Summer heat-stable peroxide systems (hydrogen peroxide) using oxygen-occlusion yet peroxide-compatible polymers, radical scavenger tuning, and water-activity control to maintain potency after 2 years.

- Remineralization & desensitizing: Nano-hydroxyapatite (n-HAp), Arginine-Calcium, and Potassium Nitrate systems, and bioadhesive film formers to extend dwell time on enamel.

Orally Disintegrating / Sublingual Films (ODF)

- High-load films (up to 25–35% actives depending on API/supplement) with taste-masking, high absorption / bioavailability and moisture control.

Atrium Scientific Oral Thin Film formulation - Micro-encapsulation to protect sensitive ingredients.

- Fast disintegration targets (≤30–60 s).

Multi-Chamber Dispensers & Two-Step Strips

- Oxygen-barrier packaging to protect peroxide or volatile actives.

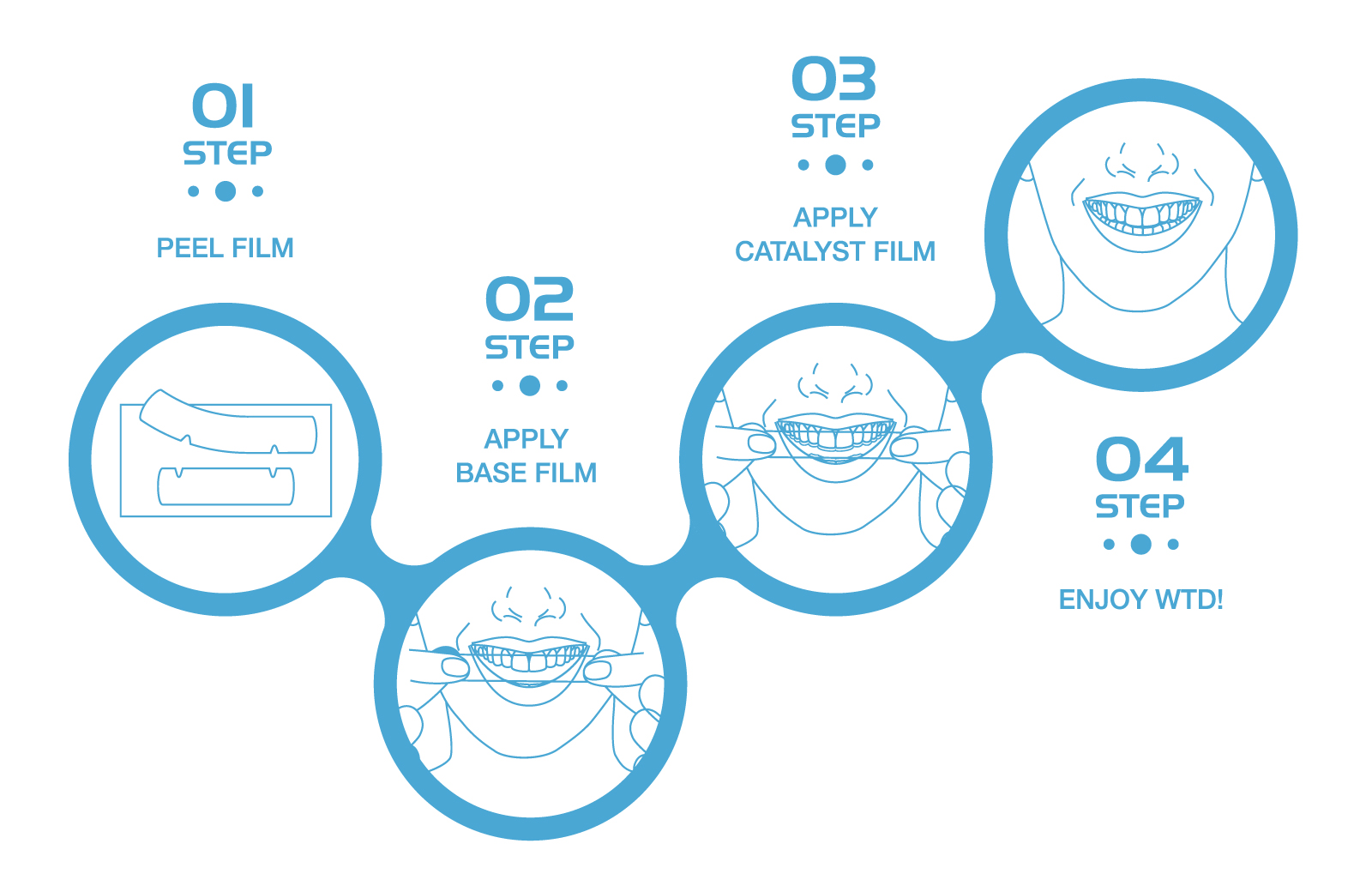

- Two-step strips that combine activator + substrate on use; validated mixing kinetics and on-tooth adhesion.

Suppository Delivery Systems

- Lipid-base matrices, melting point tuning (33–37 °C), sedimentation control for suspended actives.

- Release profiling via in-vitro dissolution.

- Guaranteed leak-proof unit-dose packaging.

Dietary Supplement Technologies

- ODF nutraceuticals, drinkable liposomal suspensions, where bad-taste or ingredient stability would defeat regular formulations.

- Label-friendly excipients, sugar-free systems, and stability-first flavor systems.

How We Work: From Problem Statement to Launch at US Speed

- Problem Framing (Week 0–1)

- Technical intake, Target Project Summary, claims guardrails, and Design for Manufacturability constraints (fill sizes, pack lines).

- Rapid Prototyping (Weeks 1–6)

- Prototype formulation sprints; build A/B/C variants internally around critical vectors (pH, rheology, compatibility, stability, taste, performance panelist testing).

- Analytical & Stress Testing (Weeks 4–8)

- Assay (titration / HPLC as needed), peroxide retention, rheometry (yield stress & thixotropy), accelerated stability (e.g., 50 °C), transport abuse (freeze-thaw), pH drifting, and packaging compatibility analysis (permeation, reaction, overall stability, etc.).

- Scale-Up + IQ/OQ (Weeks 8–10)

- Pilot batches on coater/gel mixers, line trials on actual pouches/syringes/strips; set CQAs and in-process controls (fill mass, seal strength).

- Launch (Weeks 10–16)

- Final specs, CoA templates, stability plan, artwork/label review; build safety & substantiation packets for your channel (professional/direct-to-consumer/e-commerce).

Case Studies (anonymized – documentation available under NDA)

A) Heat-Stable Professional Whitening Gel: Summer Shipping, No Cold Chain

Challenge: A professional in-office whitening brand needed a high-potency peroxide gel that survives 50 °C freight temperatures without potency drop or phase separation.

Approach:

- Engineered a water-based gel using peroxide-compatible polymers, oxygen-occlusal thickeners, and a tailored radical-scavenger matrix to slow autocatalytic breakdown.

- Matched dual-syringe viscosities (±10%) to keep dose ratio stable across 20–45 °C.

- Formulated the gel to be near-neutral pH for maximum user comfort and prevent sensitivity / pain during and after teeth whitening applications.Outcome:

- <15% peroxide loss after 30 days @ 50 °C; zero bleed or leak in packaging; rapid chairside handling (no drip, smooth spread, easy application).

- Commercialized in the US with repeat orders; post-launch complaint rate <0.3%.

B) High-Load Sublingual Film with Bitter Actives

Challenge: Deliver >35% actives in a fast-dissolving ODF with bitter notes.

Approach:

- Built a sublingual film with taste-mask micro-encapsulation /PEG plasticizer blend, and moisture-blocking pouch.

Outcome: - Disintegration ≤40 s (USP <2040>), CV of content ≤5%, and pouch residual moisture ≤3% at 6-month accelerated.

- Scaled to continuous roll-to-roll with >95% yield after die-cut.

C) Two-Step Strip for On-Contact / In-Situ Activation During Application

Challenge: Two incompatible components needed to mix only at use.

Approach:

- Designed a dissolvable activator strip with controlled-catalyzation time and a separate teeth whitening strip to direct react with the dissolvable strip on tooth contact.Outcome:

- No premature flavor degradation in 12-week shelf testing; strong consumer usability scores.

- Received a US patent (US9655818B1) for the ingenuity and innovation within 7 months.

Note: Several of our products are sold in prestige retail: Sephora, Ulta, Amazon, CVS, professional dental networks (DSO), and e-commerce; brand/retailer names and performance data are available under NDA with permission.

Quality, Compliance & Manufacturing at US Scale

- Facility: US-based; cosmetic GMP aligned (ISO 22716); device-adjacent documentation where applicable.

- QA/QC: Incoming raw verification, release testing, packaging stability, retain program, CAPA.

- Packaging: Oxygen and moisture-barrier materials; dual-barrels, airless, pouches, sachets, suppositories, and unit-dose dispensers.

- Supply chain: US and vetted global sources; alternate-vendor strategies to protect launches.

What to Bring to Your Scoping Call

- Target Product Summary: claims, channel (professional/DTC/retail), pricing requirements.

- Functional requirements: actives, flavor, peroxide level (if any), film size/thickness.

- Performance targets: viscosity, pH, dose accuracy, taste.

- Packaging preference: syringe/dual-chamber/strip/ODF pouch/suppository.

- Timelines: prototype date, pilot, first PO.

Let’s Build What Others Won’t Attempt

Based in the USA. Fast to sample. Built for scale.

- R&D kickoff: typically 2 weeks from TPP alignment.

- Pilot & scale-up: plan for 6–8 weeks after prototype lock.

- Engage us: info@atriumsci.com | Tel: (626) 380-5887. NDA available on request; we can start with a technical feasibility sprint or a full development program.

Write a Comment