Our Facility

Atrium Scientific Group, Inc. is a Made in USA contract manufacturer and formulation R&D partner based in Orange County, California. Our facility is designed to help established brands and product teams move from concept to commercialization with fewer handoffs, tighter quality control, and faster decision-making—supported by an FDA-registered facility and a cGMP-focused quality system.

Whether you need a rapid pilot run, a low-MOQ launch, or scalable production, Atrium provides the equipment, scientific expertise, and internal testing infrastructure to bring products to market faster and under budget.

What Makes Atrium a True One-Stop Shop

Our in-house lab was the key addition that equipped Atrium Scientific to provide solutions and custom formulation services to industry. We have full purity and stability testing capabilities. Our expert chemists and experienced technicians enable us to support prototyping and quick-turn jobs, as well as select production runs.

Having this level of integrated functionality speeds the development process. Turnaround is faster and quality is guaranteed.

Most brands lose time and money by splitting development, manufacturing, packaging, and testing across multiple vendors. Atrium brings these functions under one roof to reduce delays, shorten iterations, and improve consistency.

Under one roof, Atrium supports:

-

Formulation R&D + rapid prototyping

-

Process engineering and scale-up

-

Pilot runs and commercial manufacturing

-

Packaging design and dispensing system development

-

In-house testing and stability support

-

Documentation and quality controls aligned with cGMP expectations

R&D and Manufacturing Capabilities

Atrium supports multiple product categories and delivery formats—so brands can expand product lines without rebuilding their vendor network.

Suppositories

-

Formulation development and manufacturing workflows for suppository formats

-

Process optimization for consistent fill and finished product performance

-

Packaging integration support and quality checks

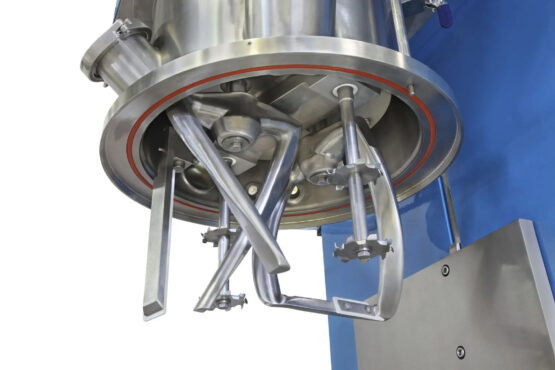

Gels, Creams, and Emulsions

-

Gel systems, creams, and emulsions with performance and sensory tuning

-

Emulsion development for stability, texture, and scale-up

-

Mixing and homogenization strategies for consistent output

Dietary Supplements & Powder Manufacturing

-

Powder blending programs designed for batch-to-batch homogeneity

-

Capsule manufacturing support (project-dependent)

-

Powdered drink mixes and functional powder systems

-

Sachet filling programs for single-serve formats (project-dependent)

Oral Thin Films / Sublingual Films (ODF)

-

Sublingual/oral thin film formulation R&D and scalable manufacturing support

-

Film casting/coating workflows for controlled thickness and uniformity

-

Taste/texture optimization and rapid iteration for market readiness

Oral Care Manufacturing (Teeth Whitening + Beyond)

-

Teeth whitening gel formulation and manufacturing support

-

Teeth whitening strip programs (coating and packaging support, project-dependent)

-

Oral care product development focused on performance and user experience

Oils, Perfumes, and Liquid Formulations

-

Oil-based and liquid formulation development

-

Fragrance and perfume-type product development support

-

Filling/packaging compatibility guidance (project-dependent)

Advanced Technology: Encapsulation, Delivery, and Dispensing Systems

Atrium helps brands differentiate with advanced processing and delivery strategies—without adding complexity to commercialization.

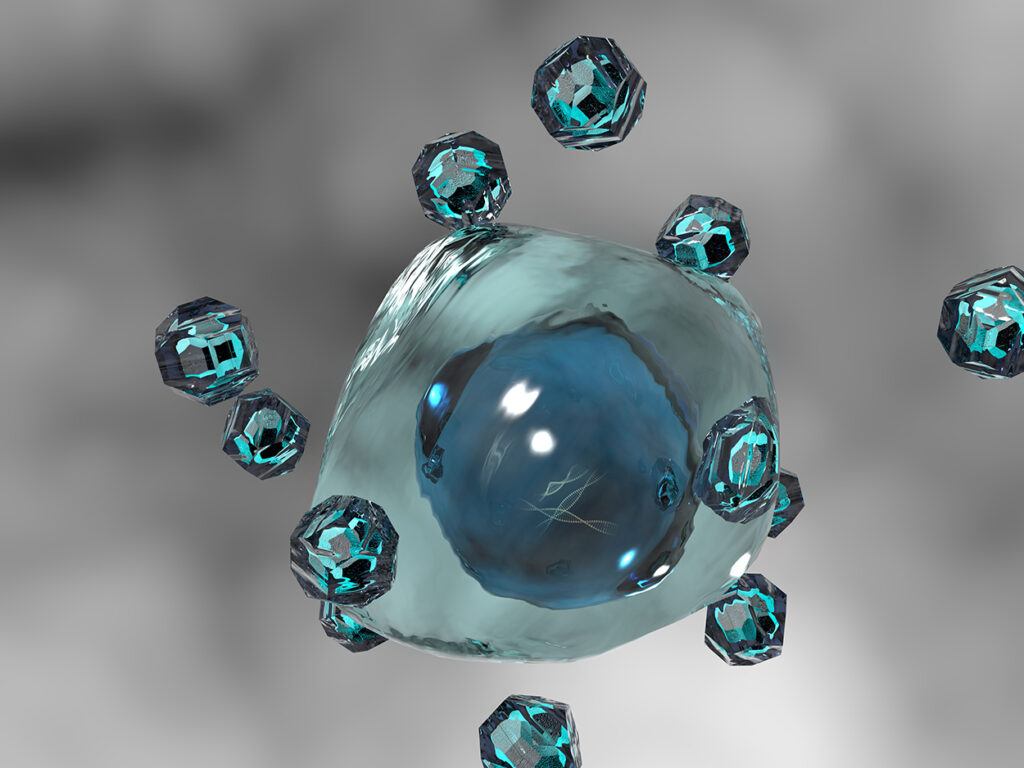

Nano & Micro-Encapsulation

-

Encapsulation approaches to improve stability, sensory experience, and performance

-

Support for solubility enhancement and controlled release concepts (project-dependent)

Dispensing System Design

-

Dispensing workflow development (compatibility, dose control, user experience)

-

Packaging system design guidance to reduce leakage, improve accuracy, and prevent failures

Patent Research & Innovation Support

-

Patent landscape review support (freedom-to-operate awareness, differentiation strategy)

-

Practical innovation guidance focused on manufacturable product improvements

In-House Testing Laboratory (Speed + Quality Under One Roof)

Atrium’s in-house testing lab reduces dependency on external labs for routine work, speeds up troubleshooting, and strengthens release confidence—especially during scale-up and early production.

In-house testing capabilities (project-dependent) include:

-

Stability and shelf-life planning support (accelerated and real-time programs)

-

Potency and assay support (method-appropriate verification)

-

Titration and wet chemistry checks

-

HPLC analytical testing support

-

Gas chromatography (GC) and liquid chromatography (LC) support

-

Incoming material checks and in-process verification (as defined per project)

Note: For testing requiring independent ISO/IEC 17025 accreditation scope, Atrium can coordinate qualified third-party laboratories while maintaining chain-of-custody and documentation controls.

Built for Speed: From Concept to Commercialization

Atrium is structured to reduce the biggest delays in product development: slow iteration cycles, vendor handoffs, and preventable manufacturing surprises.

How we help you launch faster:

-

Rapid feasibility review and process planning

-

Pilot runs to validate manufacturability before scaling

-

Integrated testing to shorten decision timelines

-

Documentation discipline to reduce rework and deviations

-

Practical cost-control decisions that keep projects on budget

Quality Systems and USA Manufacturing Confidence

Atrium operates with a cGMP-focused quality system and an FDA-registered facility (as applicable to product category), supporting controlled manufacturing and consistent output. USA-based production improves supply continuity, buyer confidence, and speed for brands that prioritize domestic manufacturing.

What this means for your brand:

-

Repeatable manufacturing with defined controls

-

Better visibility into quality and production decisions

-

Faster response when issues arise

-

Reduced logistical risk versus overseas sourcing

Who We Work With

Atrium is built to support established brands, manufacturers, and product teams that want a reliable USA-based partner for:

-

New product line expansion

-

Reformulations and performance upgrades

-

Low-MOQ market tests and pilot runs

-

Scale-up to commercial production

-

Complex projects that other labs avoid due to non-standard protocols

Ready to Build Your Next Product—Faster and Under Budget?

Atrium Scientific Group, Inc. helps brands move from idea to market with fewer vendors, tighter control, and faster execution—supported by advanced manufacturing capabilities and in-house testing.