Low MOQ from 3,000 bottles • FDA-registered facility • cGMP quality system • In-house testing

Built for Clean Labels: Encapsulate With or Without Magnesium Stearate

Many brands want to eliminate magnesium stearate to support clean-label positioning and meet consumer expectations. Atrium can run formulas with or without magnesium stearate depending on your ingredient profile, capsule size, and performance requirements.

How we support mag-stearate-free programs:

-

Flow and fill optimization

-

Alternative flow strategies

-

Pilot validation at low MOQ before scaling to high-speed output

-

Transparent formulation tradeoffs (cost, throughput, and feasibility)

If you want the cleanest label possible, we’ll help you design a manufacturing-ready powder system that fills consistently—without relying on magnesium stearate.

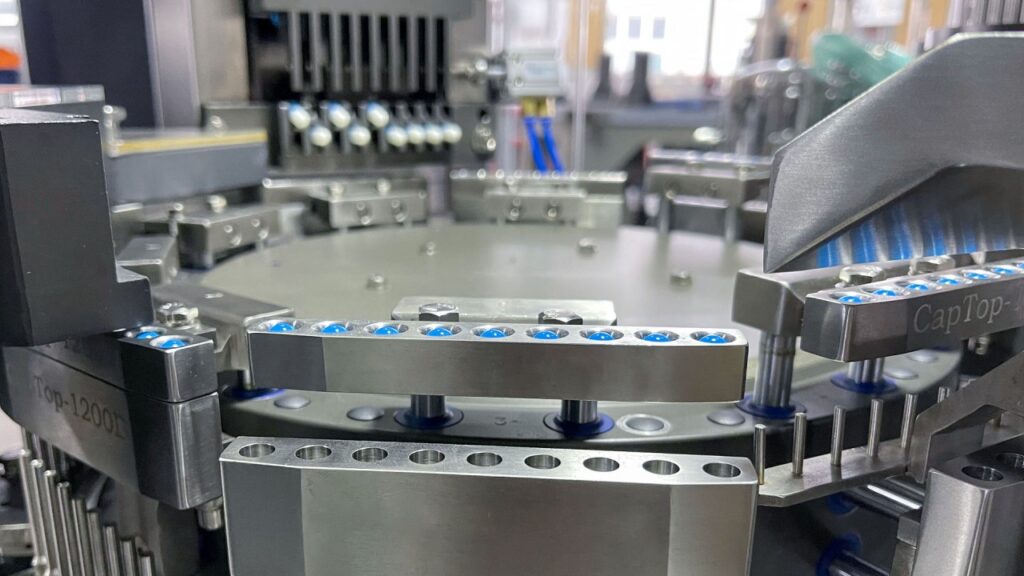

High-Speed Capsule Manufacturing Capacity (Designed to Scale)

Atrium’s capsule manufacturing line is built for brands that need speed-to-market now and scalability later.

Capability Table

| Capability | Atrium Specification | Notes |

|---|---|---|

| Encapsulation / Packaging Output | Up to 110,000 capsules/hour | Depends on capsule size, fill weight, powder flow, and packaging configuration* |

| Powder Blending | 2 blenders up to 750 kg per batch | Capacity varies by powder density and blend profile* |

| Minimum Order Quantity | From 3,000 bottles | Bottle count depends on count-per-bottle and capsule size* |

| Manufacturing Location | Made in USA (California) | Supports reshoring and domestic supply goals |

*Estimated/variable by project. Final specs confirmed during feasibility and pilot.

cGMP Quality System + FDA Registration

Atrium operates with a quality system aligned to dietary supplement cGMP requirements and maintains appropriate FDA facility registration for dietary supplement operations. Dietary supplement manufacturers, packagers, and labelers are subject to 21 CFR Part 111 cGMP requirements.

FDA food facility registration requirements are addressed under 21 CFR Part 1, Subpart H, with FDA systems supporting facility registration submissions.

Quality system highlights:

-

Master manufacturing records + controlled batch documentation

-

Ingredient receiving controls and traceability (lot-to-lot visibility)

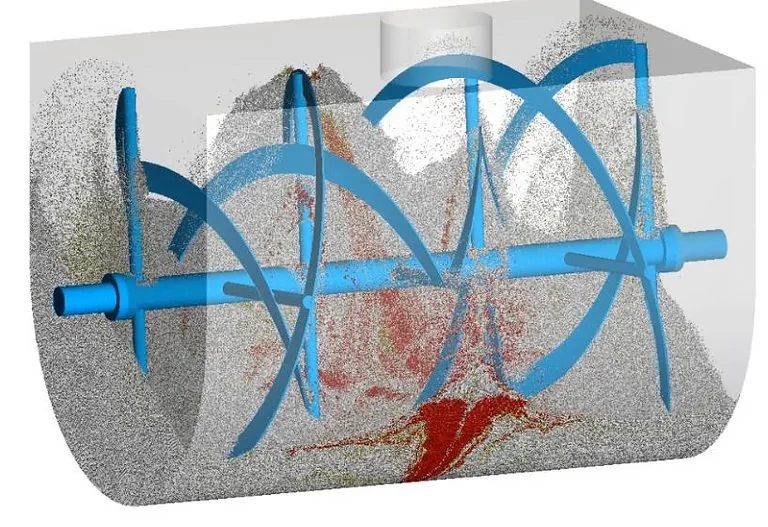

Ribbon Blender – Uniform Powder Blending -

In-process checks for weight, appearance, and process conformity

-

Controlled release workflow with documented disposition decisions

-

Deviation/CAPA practices designed for repeatable outcomes

If you have a specific customer audit checklist, we’ll align documentation packages accordingly (as applicable to your program).

In-House Testing to Move Faster & Reduce Outsourcing Delays

Atrium’s internal testing capability supports faster development cycles, tighter process control, and smoother scale-up—especially for brands running multiple SKUs or frequent production cycles.

Common testing support areas (example list):

-

Incoming material screening (project-appropriate checks)

-

In-process verification to prevent rework

-

Finished product release support (as defined in your quality agreement)

-

Stability planning support for shelf-life confidence (when requested)

For tests requiring independent ISO/IEC 17025 scope, we can coordinate qualified third-party labs while maintaining chain-of-custody controls.

What We Manufacture

Atrium supports powdered capsule programs across many supplement categories, including:

-

Vitamins and micronutrient blends

-

Botanical and functional powders (where feasible)

-

Amino acid and nootropic-style blends (flow-dependent)

-

Multi-ingredient “stack” formulas (pilot validated before scale)

Capsule options:

-

Standard capsule sizes and counts-per-bottle targets

-

Clean-label excipient strategies (including mag-stearate-free programs)

- Vegan or Non-Vegan capsules

Low MOQ From 3,000 Bottles

Not every brand wants (or needs) a massive first run. Atrium’s low MOQ starting at 3,000 bottles is built for:

-

New SKU launches by established brands

-

Market tests and channel expansion

-

Reformulations and “clean label” upgrades

-

Line extensions and seasonal releases

Why we offer low minimum order quanity:

-

Validate demand without overbuying inventory

-

Reduce cash tied up in first production lots

-

Iterate faster with real market feedback

-

Scale into higher throughput once the product proves itself

Our Manufacturing Process: Simple, Transparent, Repeatable

1) Feasibility & quote

We review your formula, capsule targets, label claims direction (non-medical), and packaging configuration.

2) Pilot run (low MOQ)

We confirm blend behavior, encapsulation consistency, and packaging workflow.

3) Scale-up planning

We optimize throughput and cost targets while maintaining quality controls.

4) Production + QC release

Documented manufacturing with defined checks and release steps.

Frequently Asked Questions (FAQ)

What is your minimum order quantity (MOQ)?

Our capsule programs can start as low as 3,000 bottles, depending on capsule size, count-per-bottle, and formula characteristics.

Can you manufacture without magnesium stearate?

Yes—magnesium stearate-free programs are available. We’ll confirm feasibility based on your powder flow, fill weight, and clean-label goals.

Where do you manufacture?

We manufacture in California, USA, supporting domestic supply reliability and “Made in USA” positioning.

How fast can we launch?

Timelines vary by formula readiness, sourcing, and packaging configuration. Pilot runs are the fastest path to confirm manufacturability and lock specifications.

Do you offer testing?

Yes—Atrium supports projects with in-house testing and can coordinate qualified third-party labs when independent accreditation scope is required.